Application of paste-like substances – efficient implementation of functional layers

.

more efficient - resource-saving - reproducible

Our experience enables us to provide our customers with reproducible and reliable applications for pasty substances of varying consistency in industrial processes. To this end, we rely on our own design, electrical system development, software development, and mechanical and electrical engineering manufacturing.

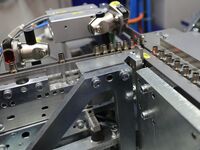

Application thermal compound

Production of a coating of rotationally symmetrical sensor housings. The housings are fed as bulk material into the fully automated system. Here they are separated and a multiple tool in which the heat conductive paste is applied. All processed parts are visually inspected. Thus, only final quality-checked workpieces enter the subsequent manufacturing process.

Coating for functional plates in fuel cells Gen1

Coating system for functional plates for solid oxide fuel cells (SOFC). The uncoated functional plates are automatically removed from a transport container and fed to the coating module. After subsequent thermal processing, the plates are automatically positioned in transport containers. The system can be operated without interruption thanks to automatic changeover units. An integrated quality control system checks the coating applied to each plate.

Coating for functional plates in fuel cells Gen2

Second-generation coating system for functional plates for solid oxide fuel cells (SOFC). The uncoated plates are automatically removed from a system carrier in the plant, labeled, and coated with two different process coatings. The integrated quality control system records the coating parameters for each plate. The coated plates are then placed in system carriers. The system can be operated without interruption thanks to automatic changeover units.

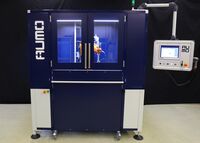

Surface structuring / Lasercell

System for the automatic surface structuring of aluminum elements as a substrate for the subsequent bonding process. This system enables the continuous surface treatment of workpieces with dimensions up to 1.300 mm x 100 mm. The system is part of an automated production line for batteries for electric vehicles.

Adhesive application car

Application of a 1-component adhesive to a glass element of motor vehicles. The adhesive is applied with a precise reproducible cross-section in order to guarantee the tightness against precipitation, splash water etc. under all climatic conditions in which the vehicle is used after installation in the vehicle.

Surface treatment / mechanical

Machine for preparing a large-area tool made of stainless steel for the subsequent production of laminated panels for aviation applications. The system mechanically removes residues from previous production cycles. The processing procedure can be adapted to the respective requirements depending on the age of the tool and the degree of contamination by selecting editable recipes via software.

CFRP bonding

Robot-supported application of a 2-component adhesive for joining a CFRP torsion bar to an aluminum workpiece. In a single process step, the system applies both ends of the CFRP rod to the outer contour and two aluminum workpieces to the inner contour. The system is equipped with a safety-oriented carrier system.

Glue application on vehicle door windows.

Automatic application system for a single-component adhesive. The adhesive bead is placed precisely on the glass element with a defined cross-section. The adhesive is dispensed precisely by a metering pump, which enables a constant volume flow depending on the speed of the application robot. The adhesive is transported through temperature-controlled hoses.